Selection of Mining Methods Based on Geotechnical Conditions and the Role of Mining Batching Plants

Introduction

Determining the mining method, whether open pit or underground, cannot be separated from the geotechnical conditions surrounding the mining area. Factors such as rock strength, geological structure, groundwater, and ore deposit depth play a major role in defining the safest and most efficient approach.

In practice, the success of mine design and operation is also supported by technical infrastructure, one of which is the mining batching plant—a key facility providing concrete materials for support systems, shotcrete, grouting, and the foundations of various mining structures.

Key Geotechnical Data

The first step in determining the mining method is collecting fundamental geotechnical data. This information serves as the foundation for assessing the technical and economic feasibility of mining.

Rock Quality & Strength

Measured using classification systems (RMR, Q-System, GSI) and mechanical parameters such as UCS, cohesion (c), and internal friction angle (φ).

➝ Weak rock complicates the design of steep slopes or underground openings.

Geological Structure

Discontinuities such as faults and weak planes control the likelihood of slope failure (in open pit) or roof collapse (in underground mining).

➝ The orientation of weak planes often becomes a key determinant of the method.

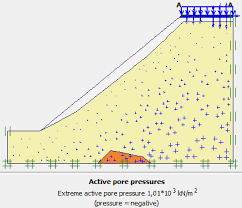

Groundwater

Pore water pressure can reduce the shear strength of rock.

➝ Common solutions include dewatering through wells, drainage systems, or grouting.

Depth & Natural Stress

The deeper the deposit, the greater the vertical and lateral stresses.

➝ This condition limits slope steepness and requires stronger underground supports.

Geotechnical Implications for Mining Method Selection

Open Pit Mining Method

This method is ideal for near-surface ore deposits with an economically feasible stripping ratio (SR).

Key factors include:

- Slope Stability: Bench angle, height, and berm width must maintain a safety factor ≥ 1.2.

- Deformation Control: Implemented via radar or laser monitoring to detect excessive movement.

- Role of Batching Plant: Supplies concrete for slope protection, haul road structures, and stormwater barriers, like ensuring slope stability and operational efficiency.

Underground Mining Method

When deposits lie at significant depths or open-pit slopes become too risky, underground methods are preferred. Each technique has specific geotechnical requirements:

- Room & Pillar: Requires strong rock pillars, which can be reinforced with shotcrete from the batching plant.

- Cut-and-Fill: Suitable for weak rock masses, supported by backfill mixtures containing concrete.

- Longhole Stoping: Demands strong wall rock, often reinforced with shotcrete and rock bolts.

- Block Caving: Ideal for fractured rock, requiring massive grouting systems to control caving.

Across all these methods, the batching plant serves as the main source of shotcrete and grout materials, ensuring rapid delivery of fresh concrete to underground work areas for timely support installation.

Integration of Batching Plants into Geotechnical Systems

A batching plant is not merely a concrete-mixing facility, it is an integral part of a modern mining geotechnical system.

In complex mine designs, concrete acts as a structural element as vital as the rock itself, helping to maintain stability, protect workers, and extend the life of operations.

Technical Roles of Batching Plants in Mining Operations:

- Provide shotcrete for slope and tunnel wall support.

- Supply grouting materials for filling voids and reinforcing foundations of heavy equipment such as crushers, conveyors, and shaft collars.

- Support drainage infrastructure, mine water ponds, and runoff control structures (sumps).

- Produce concrete slabs for workshops, ramps, and haul roads to withstand heavy dynamic loads.

The placement of batching plants must consider proximity to work areas, material access, and mine water systems. Fixed batching plants are more efficient for large-scale mines with high concrete demand, while mobile batching plants are more flexible for underground or remote-site operations.

Decision Framework

Mining method selection cannot rely on a single factor. A multi-criteria decision framework is required, considering geotechnical, economic, safety, and environmental aspects.

Approaches such as the Analytic Hierarchy Process (AHP), scoring systems, or Monte Carlo simulations help balance the weight between geotechnical risks and operational costs.

Key Determining Parameters:

- Stripping Ratio (SR): If too high → underground mining is preferable.

- Slope Stability: If slope failure risk is high → open pit is limited.

- Groundwater Volume: Large amounts increase risks for both methods.

Infrastructure Readiness: Availability of batching plants and support facilities greatly affects efficiency and safety.

Conclusion

Selecting a mining method is a strategic decision that must begin with comprehensive geotechnical analysis. Rock quality, geological structure, groundwater conditions, and deposit depth form the foundation.

However, long-term success also depends on the readiness of support systems, particularly the mining batching plant, which ensures a consistent supply of high-quality shotcrete, grout, and concrete to maintain mine stability.

By integrating geotechnical analysis with construction infrastructure such as batching plants, mining method decisions can be made safely, efficiently, and sustainably, resulting in operations that are more productive, stable, and future-ready.

References

- Ataei et al. (2008). Mining Method Selection by AHP.

- Hebblewhite (2019). Geotechnical Risk in Mining.

- Tutluoğlu (2013). Geotechnical Considerations in Mining Method Selection.

- Sika AG (2022). Concrete and Shotcrete Systems for Underground Mining.