In the mining world, risk is not just about visible dangers. Slope failure, tailings dam collapse, flooding, gas explosions, equipment breakdowns, and human errors are real threats. Technically, however, risk is defined as the uncertainty associated with the likelihood and impact of an event.

One of the most critical aspects of geotechnical risk management is slope protection, an engineered system designed to maintain slope stability and prevent erosion, landslides, or rockfalls that may endanger workers and equipment.

That’s why measuring mining and slope protection risk is a process that cannot be ignored. Through a systematic approach, companies can determine whether a mine is feasible to operate, how mitigation strategies should be developed, and how safety and sustainability can be ensured.

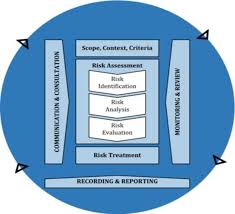

The Risk Measurement Cycle

International standards such as ISO 31000 and ISO 31010 emphasize that risk must be managed through a continuous cycle. Once risks are assessed and controlled, slope protection systems must also be regularly evaluated, as geotechnical conditions evolve over time.

Key steps include:

- Establishing context – Understanding geological, hydrological, and slope design conditions.

- Risk identification – Recognizing potential slope failures, erosion, and rock deformation.

- Risk analysis – Assessing probability and impact using qualitative and quantitative methods.

- Risk evaluation – Prioritizing high-risk areas, especially in landslide-prone zones.

- Mitigation – Designing slope protection using shotcrete, rock bolts, geogrids, drainage, and vegetation reinforcement.

- Monitoring & review – Tracking slope deformation and protection performance.

- Communication – Ensuring geotechnical, operational, and management teams understand current risks and control measures.

Risk Analysis Techniques

Several techniques are commonly applied in mining to assess slope and protection system risks:

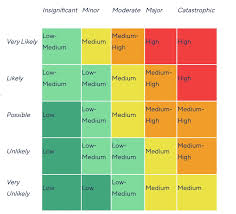

- Probability–Impact Matrix: Determines priority based on likelihood and severity.

- FMEA/FMECA: Analyzes potential failure modes in slope protection systems or monitoring devices.

- Fault Tree, Event Tree, Bow-Tie: Illustrate how localized failures (e.g., cracks in shotcrete) could trigger large-scale collapses.

- QRA & Monte Carlo Simulation: Provide quantitative predictions of slope failure probability based on geotechnical parameters.

- Human Reliability Analysis (HRA): Evaluates potential human errors during installation or inspection of slope protection systems.

Common Mining Risks and Slope Protection Solutions

Risks frequently analyzed in the mining sector include:

- Slope stability: Evaluated using the Factor of Safety (FoS) through limit equilibrium or finite element analysis.

➜ Controlled with shotcrete, rock bolts, and drainage systems. - Tailings dam failure: Mitigated through filter drains and water-retention structures.

- Rockfalls: Prevented using rock mesh, cable bolts, and catch fences.

- Underground flooding: Managed via pumping systems and wall protection.

- Environmental risks (erosion): Reduced through stabilization vegetation and surface sealing.

Implementation Challenges

Measuring mining risk is never straightforward. Several challenges must be considered:

- Uncertainty in geotechnical data, especially in fractured rock zones.

- Interacting risks, such as erosion accelerating slope instability.

- Limited technical resources or software for advanced simulations.

- Human and safety culture factors affecting protection effectiveness.

Conclusion

Assessing mining and slope protection risks is not merely a technical exercise, it’s a long-term risk management strategy. A scientific approach, combined with real-time monitoring, regular inspections, and effective team communication, ensures that mining operations remain safe, efficient, and sustainable.

References

- ISO 31000 / ISO 31010 – Risk Management Framework

- Worldsensing – Risk Management in Mines

- MSHA – Quantitative Analysis of Coal Mine Dust Exposure