PT Aptekindo Mitra Solusitama (AMS)

Integrated Geotechnical and Construction Solutions for Mining and Infrastructure Projects.

PT APTEKINDO MITRA SOLUSITAMA is a trusted partner delivering comprehensive civil and geotechnical engineering solutions, specializing in underground works, slope stabilization, specialized foundations, and environmental protection. We serve a wide range of industries—particularly mining and infrastructure—through technical services including shotcrete, rock bolting, grouting, geosynthetics installation, and facility maintenance. With a solid track record in national strategic projects, we are committed to providing engineering-driven solutions built on quality, safety, and cost-efficiency.

See our expertise in action—project spotlightProducts

Engineering-Grade Products for Mining, Infrastructure, and Civil SolutionsShotcrete & Concrete Admixtures

High-performance chemical solutions to enhance concrete and shotcrete behavior in mining and structural applications.

Learn MoreGeosynthetic & Ground Stabilization Materials

Geotechnical materials for soil reinforcement, erosion control, and effective drainage systems in mining and infrastructure.

Learn MoreSteel Support & Rock Reinforcement Components

Precision-engineered steel systems for underground support and slope protection.

Learn MoreBuilding & Structural Materials

Specialized construction materials for structural repair, protective coatings, and waterproofing systems.

Learn MoreWater System Solution

Durable piping systems and fittings for drainage, mining slurry, and industrial fluid handling.

Learn MoreNon-Explosive Demolition Agents (NEDA)

Eco-friendly agents designed for silent and vibration-free rock or concrete demolition.

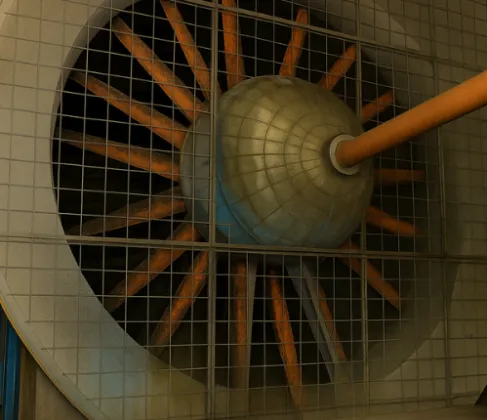

Learn MoreMine Ventilation Systems

Reliable airflow solutions for underground mining operations.

Learn MoreMine Safety Solutions

Emergency systems for personnel safety in hazardous mining conditions.

Learn MoreServices

Artificial Ground Support

Slope and rock mass stabilization using mechanical and chemical systems.

Underground Works

Comprehensive underground development services from excavation to ground consolidation.

Batching Plant Operation

Quality control and operation of batching plants for consistent concrete production.

Geosynthetic Solutions

Installation of synthetic materials for soil reinforcement and containment systems.

Geotechnical Solutions

Engineering solutions for foundation support, rock anchoring, and retaining structures.

Mining and Civil Works Infrastructures

Construction and refurbishment services for industrial facilities and infrastructure.

Portfolio

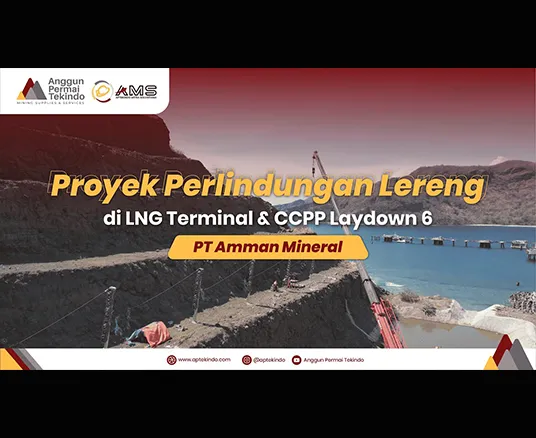

Slope Protection at LNG Terminal & CCPP

PT Amman Mineral

Slope Protection at UG Kopra

PT Tambang Tondano Nusajaya

Rockfall Barrier

PT Amman Mineral

Geocell Concrete Infill at Low Flow Diversion

PT Archi Mining

Engineering Office

Emerald Avenue, Block EA/A-05, Sector 7, Bintaro Jaya, Pondok Aren District, South Tangerang, Banten 15227 – Indonesia

See our expertise in action—project spotlight

Shotcrete & Concrete Admixtures

High-performance chemical solutions to enhance concrete and shotcrete behavior in mining and structural applications. We offer a complete range of admixtures including accelerators, superplasticizers, retarders, and micro/macro fibers to improve bonding, reduce setting time, and ensure durability in extreme conditions.

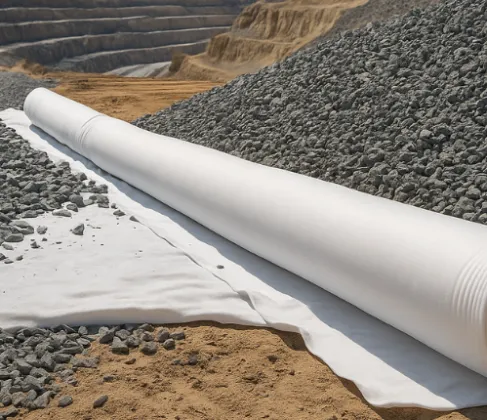

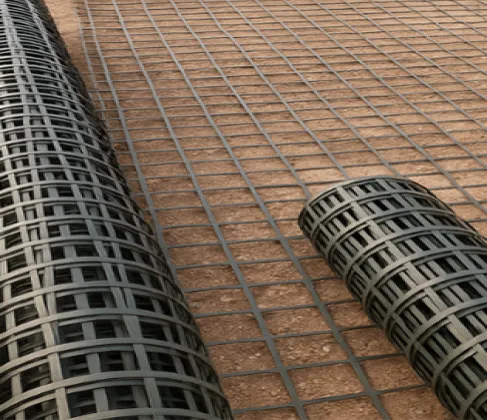

Geosynthetic & Ground Stabilization Materials

Geotechnical materials for soil reinforcement, erosion control, and effective drainage systems in mining and infrastructure. Products include:

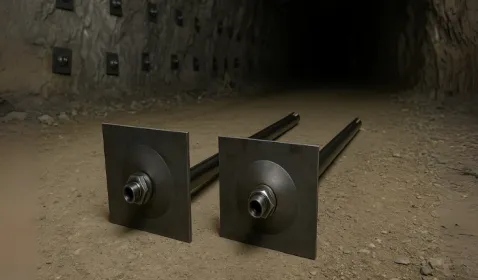

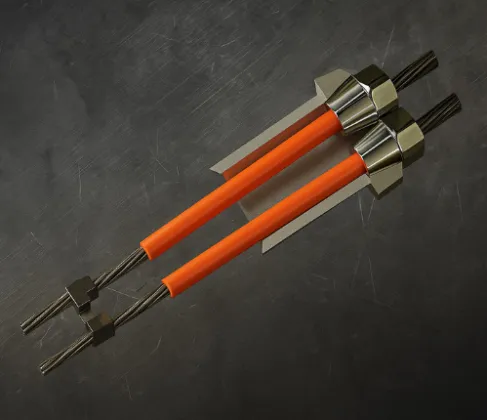

Steel Support & Rock Reinforcement Components

Precision-engineered steel systems for underground support and slope protection. Our range includes:

Building & Structural Materials

Specialized construction materials for structural repair, protective coatings, and waterproofing systems. Our offerings include grouting compounds, waterproofing membranes, protective coatings, and industrial-grade flooring solutions for harsh environments.

Pipes & Drainage Accessories

Durable piping systems and fittings for drainage, mining slurry, and industrial fluid handling. Includes:

Non-Explosive Demolition Agents (NEDA)

Eco-friendly agents designed for silent and vibration-free rock or concrete demolition. Perfect for underground, urban, or sensitive environments where traditional blasting is not viable.

Mine Ventilation Systems

Reliable airflow solutions for underground mining operations. Products include:

Mine Safety Solutions

Emergency systems for personnel safety in hazardous mining conditions.

Slope Protection at LNG Terminal & CCPP

In addition to the rockfall barrier system, artificial ground support measures such as dry shotcrete application and rock bolting have been implemented to enhance slope stability by mitigating the risk of wedge failures and providing surface protection. The slope was reinforced using K250-grade dry shotcrete with a 10 cm thickness, combined with composite steel reinforcement comprising M5 black steel wire mesh rolls (2.1 m × 54 m) and 0.8-meter-long friction bolts with a 33 mm diameter. For deeper anchorage, fully grouted thread bars (25 mm diameter, 4.0 m length, 3-inch hole diameter) were installed, with pull-out tests showing an acceptance load of 120 kN.

An in-situ destructive test using 32 mm diameter thread bars with a 1.0 m bond length and 3-inch hole diameter revealed bond stress values ranging from 661 to 945 kPa, with failure occurring at the grout-rock interface. These test results offer valuable insight and should be utilized to further optimize future slope protection designs.

Slope Protection at UG Kopra

The slope protection system for the UG Portal Kopra is designed to ensure long-term stability and safety through a combination of advanced reinforcement techniques. It includes the installation of cable bolts using PC single strand (15.24 mm, 1,860 MPa), each providing 12 tons of capacity per hole, with a total length of 10 meters (7 meters bond length and 3 meters free length), spaced at 2-meter intervals with a 3-inch hole diameter.

Additionally, fully grouted 25 mm diameter thread bars with a yield strength of 400 MPa are installed, offering 5 tons per hole at a length of 3 meters, also spaced 2 meters apart. Sikagrout 200 PT is used as the grouting material, offering high compressive strength, early pull-out capability (within 7 days), zero bleeding, and increased productivity with consistent performance.

Dry shotcrete is applied using fiber-reinforced mixtures, manually or with a Carmix self-loading mixer (3.5 m³ capacity). Friction bolts combined with wire mesh serve as composite support with shotcrete. For additional rockfall isolation and corrosion resistance, a steel-plastic geogrid replaces traditional chainlink mesh, enhancing durability along the slope face.

Rockfall Barrier

A rockfall barrier (RFB) system with an energy absorption capacity of 2000 kJ has been installed along a 350-meter stretch of slope benches, spaced every 10 meters, to safeguard the LNG tank from potential rock boulder impacts resulting from geological discontinuities. This barrier placement was based on comprehensive rockfall trajectory simulations. The installation scope included grouting of rock anchors, erection of 5.0-meter H-beam steel posts, and the placement of both cables and mesh, all of which were efficiently completed within a two-month period.

The RFB 2000 kJ system comprises a high-resistance, hot-dip galvanized barrier structure capable of absorbing up to 2000 kJ of energy, with a residual height of 71.1% of its nominal height and a maximum elongation of 6.42 meters. The lateral and upslope anchors utilize 20 mm diameter flexible high-strength cables with a tensile capacity of 302 kN, drilled to a depth of 4.0 meters with 3-inch diameter holes. Acceptance test loads were recorded at 251 kN for lateral anchors and 182 kN for upslope anchors. Foundation anchors consist of fully grouted 32 mm diameter thread bars, also embedded to 4.0 meters with 3-inch diameter holes, and demonstrated an acceptance load of 189 kN.

Geocell Concrete Infill at Low Flow Diversion

Geocell concrete infill combined with friction bolting has been successfully implemented for low-flow river diversion, offering a more effective and cost-efficient alternative to conventional methods such as concrete pouring and concrete canvas. This innovative approach enhances structural integrity while optimizing material usage and installation time. The system utilizes 10 cm thick HDPE geocells filled with K300-grade wet shotcrete reinforced with synthetic fibers to improve durability and crack resistance. To further stabilize the structure, 33 mm diameter friction bolts with a length of 1.50 meters are applied, anchoring the geocell system securely to the ground.

Artificial Ground Support

Slope and rock mass stabilization using mechanical and chemical systems.

Underground Works

Comprehensive underground development services from excavation to ground consolidation.

Batching Plant Operation

Quality control and operation of batching plants for consistent concrete production.

Geosynthetic Solutions

Installation of synthetic materials for soil reinforcement and containment systems.

Geotechnical Solutions

Engineering solutions for foundation support, rock anchoring, and retaining structures.

Mining and Civil Works Infrastructures

Construction and refurbishment services for industrial facilities and infrastructure.