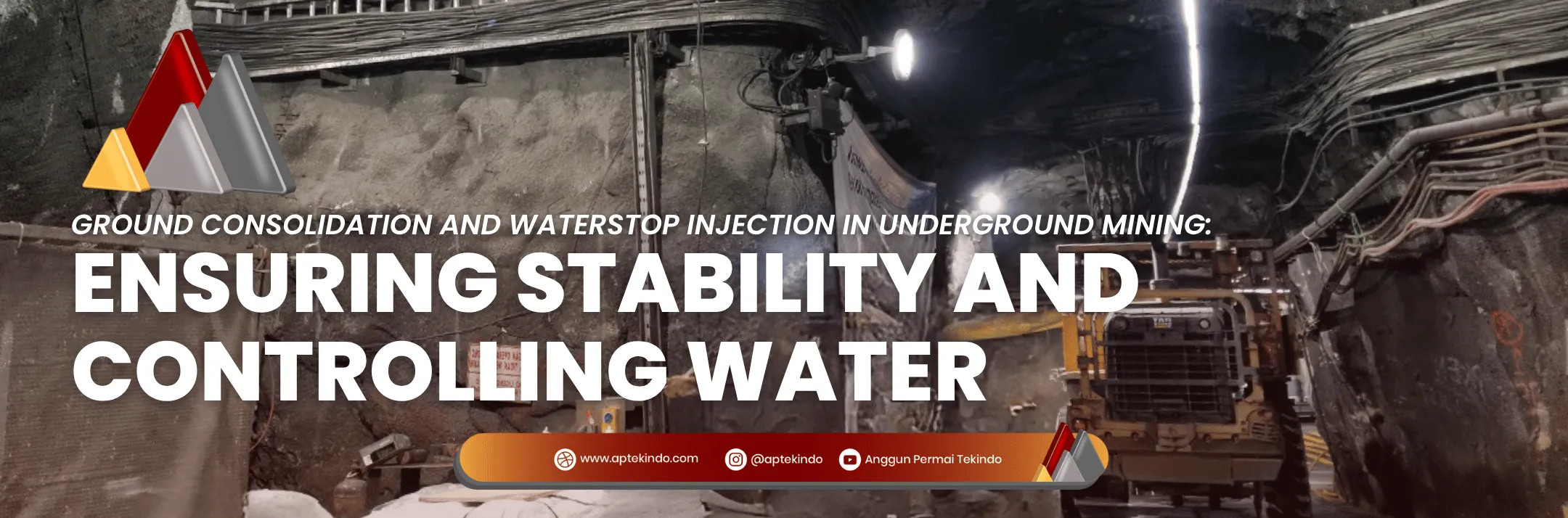

Underground mining faces two main challenges: the stability of rock and soil masses around the mine openings, and the control of water ingress into the mining spaces. Both are crucial to ensure that mining operations can run safely, efficiently, and sustainably. Ground consolidation and waterstop injection methods are widely applied to effectively address these issues.

1. Ground Consolidation in Underground Mining

One of the main challenges in underground mining is the complex and high-risk environment, particularly due to the high pressure from unstable rock and soil masses. These conditions can potentially cause collapses and deformations around tunnels or mine chambers, which can be fatal. Additionally, the presence of soft soil or uneven weathered layers adds uncertainty, making it even harder to predict the stability of the mining zone.

A solution to this challenge is ground consolidation, which strengthens the soil and rock around the excavation zones. This technique prevents deformation and tunnel wall collapse, making mining operations safer and minimizing the risk of accidents.

Commonly used methods:

- Grouting (Cement or Resin Injection):

Injecting grout (a mix of cement, resin, or chemicals) into rock fractures or soft soils around tunnels to bind soil/rock particles and increase mechanical strength. This is the primary method for ground consolidation in underground mining. - Jet Grouting:

A high-pressure injection method that mixes surrounding soil with grout to form solid and stable soil-cement columns. - Compaction Grouting:

Injecting thick grout to compact and fill voids in soft soils, reducing settlement and improving stability.

2. Waterstop Injection in Underground Mining

Water ingress is also a major issue in underground mining. Water entering from aquifer layers or rock fractures can cause flooding, disrupt mining operations, and accelerate structural deterioration. Moreover, water presence can lead to equipment corrosion and lower the overall quality of the mining area.

To address this, waterstop injection is a key solution. This method is used to seal cracks or joints in underground concrete structures such as portals, tunnel linings, and ore storage rooms. As a result, waterstop injection prevents water seepage, ensuring the safety and smooth operation of underground mining.

Common injection materials used:

- Polyurethane (PU) Resin: Expands rapidly upon contact with water, sealing active leaks.

- Epoxy Resin: Used to seal stable structural cracks (passive leaks).

- Cementitious Grout: Used for sealing joints and larger gaps.

Waterstop injection procedure:

- Identify leak points through inspection and moisture measurement.

- Drill injection holes at crack or joint locations.

- Inject waterstop material using controlled pressure.

- Material expands/hardens, forming a watertight barrier.

Conclusion

In underground mining, Ground Consolidation (via various grouting and compaction methods) and Waterstop Injection (using resin and specialized grouts) are crucial engineering solutions to maintain structural stability and control water ingress. Proper implementation of both methods can reduce accident risks, enhance operational efficiency, and extend the mine's lifespan.

Sources:

- ACI (American Concrete Institute) Committee 224. Report on Cracking of Concrete Structures, ACI 224R-01, 2001.

- Das, Braja M. Principles of Geotechnical Engineering, 9th Edition, Cengage Learning, 2013.

- Neville, Adam M. Properties of Concrete, 5th Edition, Pearson, 2011.

- Technical Guidelines from US Army Corps of Engineers. Engineering and Design – Ground Improvement, USACE, 2001.