In the world of underground mining, safety is not just about personal protective equipment or operational procedures it's also about how we keep the rocks in place. One of the crucial aspects that determine the stability of work beneath the Earth's surface is the rock support system.

What is a Rock Support System in Underground Mining?

A rock support system is a technique and set of tools used to stabilize the rock around the mine openings, such as tunnels, stopes, and shafts. Its primary objectives are to:

- Prevent rockfalls due to natural fractures or underground pressure.

- Maintain the integrity of the mine structure.

- Protect workers and equipment in the work area.

This system is divided into two main categories:

- Active Support (Rock Reinforcement)

Works by binding the rocks together, allowing them to support themselves. It typically includes:- Mechanical rockbolts (tensioned bolts)

- Grouted dowels

- Steel cables (cable bolts)

- Passive Support

Acts as an additional barrier once the rock begins to move. Its components include:- Mesh (wire mesh)

- Straps (steel plates)

- Shotcrete (sprayed concrete)

- Steel arches (framework)

Common Types of Supports Used

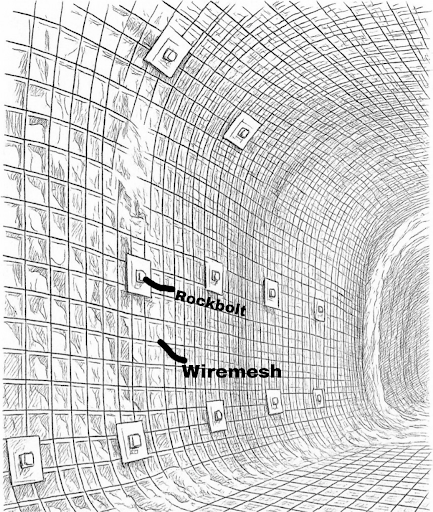

A. Mechanical Rockbolts (Tensioned Rockbolt)

Figure 1. Mechanically anchored, tensioned rockbolt

- Installed with an anchoring system and tensioned with a special tool.

- Effective for holding loose rock blocks due to natural fractures or blasting.

- Ideal for hard and stable rock conditions.

- Disadvantages: Can lose tension due to blast vibrations, and are prone to corrosion when exposed to acidic water.

B. Grouted Dowels

Figure 2. Untensioned, grouted dowel

- Steel rods inserted into drilled holes and cemented in place.

- No need for tensioning, making installation simpler.

- Durable and continues to function even if the outer part is damaged.

- Must be installed before the rock undergoes significant deformation.

C. Cable Bolts

Figure 3. Grouted cable bolt

- Made from flexible steel cables that are grouted along the length of a drilled hole.

- Used to support larger openings or weak rock.

- Can be tensioned or left passive depending on design needs.

- Very effective in narrow areas like stopes or active fault zones.

Surface Support System Additions

A. Mesh

Figure 5. Mesh

- Wire mesh installed between bolts to prevent small rocks from falling.

- Available in chainlink (flexible) and welded mesh (rigid).

- Especially important in areas with many small fragments due to blasting..

B. Straps

Figure 6. Strap

- Long steel plates installed across rockbolts to prevent thin or slabby rock layers from detaching.

- Very effective when used against rock fracture directions.

C. Shotcrete

Figure 7. Typical dry-mix shotcrete operation

- Sprayed concrete applied directly to rock surfaces.

- Keeps the surface solid, prevents small collapses, and strengthens the bond between rock fragments.

- Now enhanced with microsilica and steel fibers, making it stronger and more resistant to vibration damage.

- Ideal for long-term areas like ramps, haulage, and transportation routes.

D. Steel Arches

Figure 8. Steel arches

- Curved steel frames used in areas with very weak rock or active fault zones.

- Passive in nature: only active once the rock begins to move.

- Must be installed with proper blocking to ensure the rock load is evenly distributed across the steel structure.

Factors Affecting the Selection of a Rock Support System

Choosing the right support system is not arbitrary. Engineers and geotechnicians consider several factors:

- Geological conditions: rock type, fracture patterns, weak zones.

- Underground stress (in-situ stress): pressure levels affect the type of support needed.

- Size of the mine opening: larger openings require longer and stronger support systems.

- Opening lifespan: whether the opening is for short-term (temporary access) or long-term use (ramps, shafts, crusher stations).

- Installation ease: efficient installation is crucial to maintain productive mining cycles.

Why Is Support Important in Mining Operations?

Safety and productivity go hand in hand. The right support system not only:

- Protects lives and company assets,

- Reduces downtime due to collapses,

- Increases operational efficiency,

Ensures that the mine operates sustainably and economically.

Conclusion

Rock support is more than just a structure; it’s an active protection against underground risks. With the right system selection, careful planning, and adequate worker training, we can create a strong, safe, and productive underground mine.