Slope modeling is a crucial stage in open-pit mine design to ensure that pit walls remain stable, safe, and economical. Slopes that are too steep are prone to failure, while slopes that are too shallow increase operational costs. In practice, the shape of the slope or pit wall develops along with the excavation process, and the main challenge is determining the optimal slope angle and geometry: steep enough to be economical, but still safe enough to prevent slope failure. Much like cutting a cake, slices that are too steep crumble easily, while slices that are too shallow waste material. This balance is at the heart of slope modeling in mine design.

Stages of Slope Modeling

1. Data Collection

The first step is to gather comprehensive site data:

- Geological data to determine rock types, stratification, fractures, and faults.

- Geotechnical data including mechanical parameters such as cohesion, internal friction angle, unconfined compressive strength (UCS), and elastic modulus.

- Hydrogeological data to understand groundwater conditions, including water table depth and rock permeability.

- Topographic data from surveys or digital elevation models (DEM/DTM).

Together, these datasets form the “health profile” of the rock mass before excavation begins.

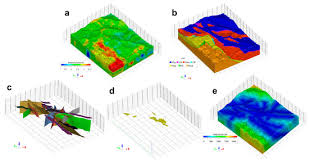

2. Geological and Geotechnical Modeling

Once data is collected, the next step is to create a three-dimensional (3D) model. This model displays the distribution of strong rocks, weak zones, fractured areas, and potential failure planes. With such a model, planners can visualize subsurface conditions more accurately than with borehole logs or 2D maps alone.

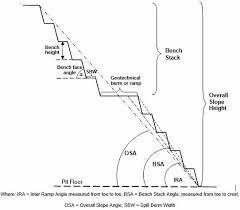

3. Initial Slope Geometry Design

Based on the geological and geotechnical model, the initial slope geometry is defined, including bench height, berm width, bench face angle, and overall slope angle. This stage is similar to designing a staircase: one must decide the step height, tread width, and overall steepness to ensure both safety and usability.

4. Slope Stability Analysis

The designed slope geometry is then tested through stability analysis using several methods:

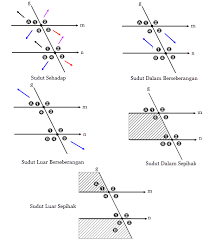

- Empirical methods such as RMR, Q-System, or Q-Slope, providing preliminary estimates based on field experience.

- Limit equilibrium methods (LEM), which calculate the factor of safety (FoS) by balancing resisting and driving forces along a potential slip surface.

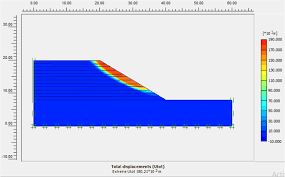

- Numerical methods such as the Finite Element Method (FEM) or Discrete Element Method (DEM), allowing detailed computer simulations of stress distribution, deformation, and groundwater effects.

Through these approaches, planners can determine whether a slope is stable or requires modifications before mining operations proceed.

5. Slope Geometry Optimization

If analysis results indicate instability risks, slope geometry must be optimized. This may involve widening berms, reducing slope angles, or lowering bench heights. The main goal is to achieve the minimum factor of safety required, typically between 1.2 and 1.5 depending on applicable standards.

6. Slope Stabilization

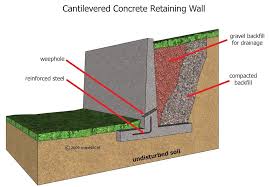

Beyond geometry optimization, additional stabilization measures are often necessary, especially in weak or water-bearing rock masses. Common strategies include:

- Drainage systems to reduce pore-water pressure.

- Mechanical reinforcement such as rock bolts, soil nails, or cable bolts to strengthen the rock mass.

- Geosynthetics or mesh to hold surface layers and prevent raveling.

- Buttresses or additional berms at the slope toe to improve stability.

- Reprofiling to adjust slope geometry to a safer angle.

By combining these methods, slopes can withstand rainfall, blasting vibrations, and long-term weathering.

7. Slope Protection

Once the slope is structurally stable, slope protection ensures its long-term performance against weathering, runoff, and erosion.

Common protection techniques include:

- Shotcrete coating to shield exposed rock faces, often reinforced with wire mesh.

- Hydroseeding or vegetation cover to reduce erosion and enhance environmental recovery.

- Geotextiles and erosion control mats to stabilize fine-grained surfaces.

- Protective coatings or sealants to minimize water and chemical ingress.

Surface drainage systems to divert rainfall and prevent localized erosion.

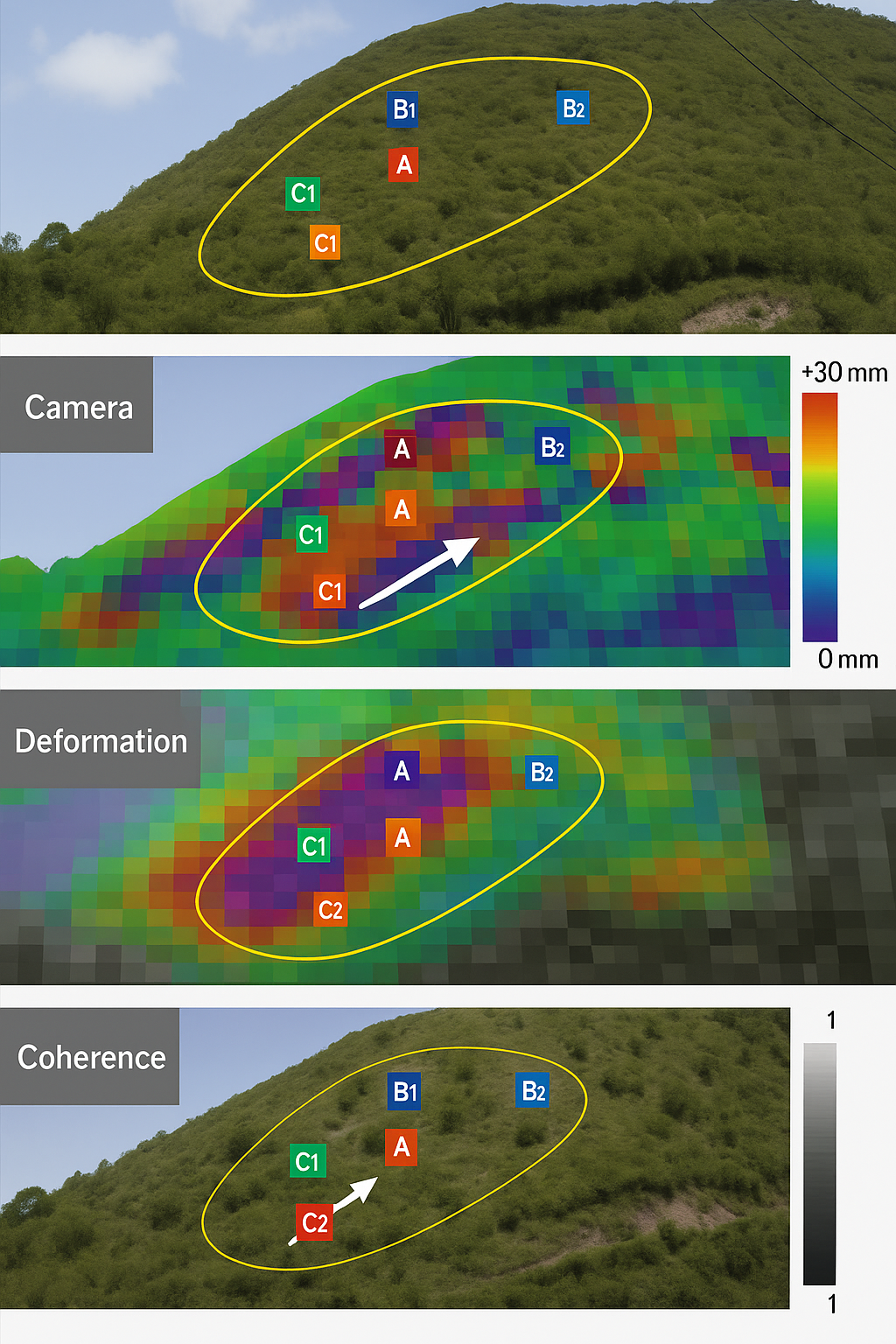

8. Monitoring and Back Analysis

Even after construction, slope stability must be monitored continuously. Instruments such as inclinometers, radar, and piezometers are used to detect ground movement. If displacements are observed, the data is applied in back analysis to update geotechnical parameters and improve the accuracy of the model. This adaptive process ensures that slope design remains aligned with real-world conditions.

Conclusion

Slope modeling in mine design is a multidisciplinary process that integrates geology, geotechnical engineering, hydrogeology, and mining engineering. Its stages include data collection, 3D modeling, geometry definition, stability analysis, optimization, stabilization, and monitoring. The ultimate goal is clear: to ensure that mine slopes are safe for workers, stable in the long term, and economically viable.

In essence, slope modeling is both a science and an art of balancing safety and efficiency in open-pit mining operations.

References

- Hoek, E. (2009). Fundamentals of Slope Design. Rocscience.

- Abramson, L.W. (2002). Slope Stability and Stabilization Methods. Wiley.

- Frontiers in Earth Science (2024). Numerical and Probabilistic Approaches in Slope Stability Analysis.

- Nature Scientific Reports (2024). Dynamic Optimization of Open Pit Slope Design Under Uncertainty.