Every open-pit mine faces a major challenge: slope stability. A slope that fails to withstand its load can block haul roads, halt production, damage heavy equipment, and even endanger workers’ lives. That’s why slope stability analysis is not just a formality—it is the key to operational continuity.

Structural Data: The Foundation of Analysis

Sumber: google.com

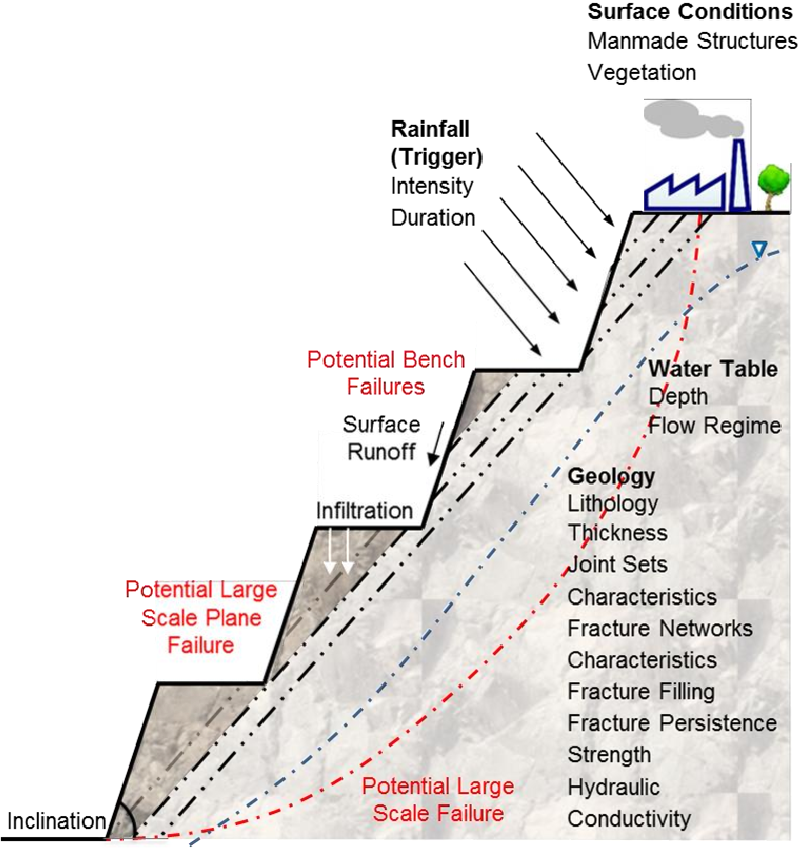

Before any calculation begins, complete data is essential. This data includes:

- Slope Geometry → height, angle, slope length.

- Geology & Discontinuities → rock type, fractures, faults, weak layers.

- Geotechnical Data → results of triaxial, direct shear, and UCS tests to determine cohesion (c) and internal friction angle (φ).

- Hydrogeology → groundwater table position, pore pressure.

- Mining Operations → blasting patterns, haul traffic, pit design changes.

📌 Example: A triaxial test in the laboratory might yield cohesion of 80 kPa and an internal friction angle of 28°. These numbers serve as the main input for calculating the factor of safety.

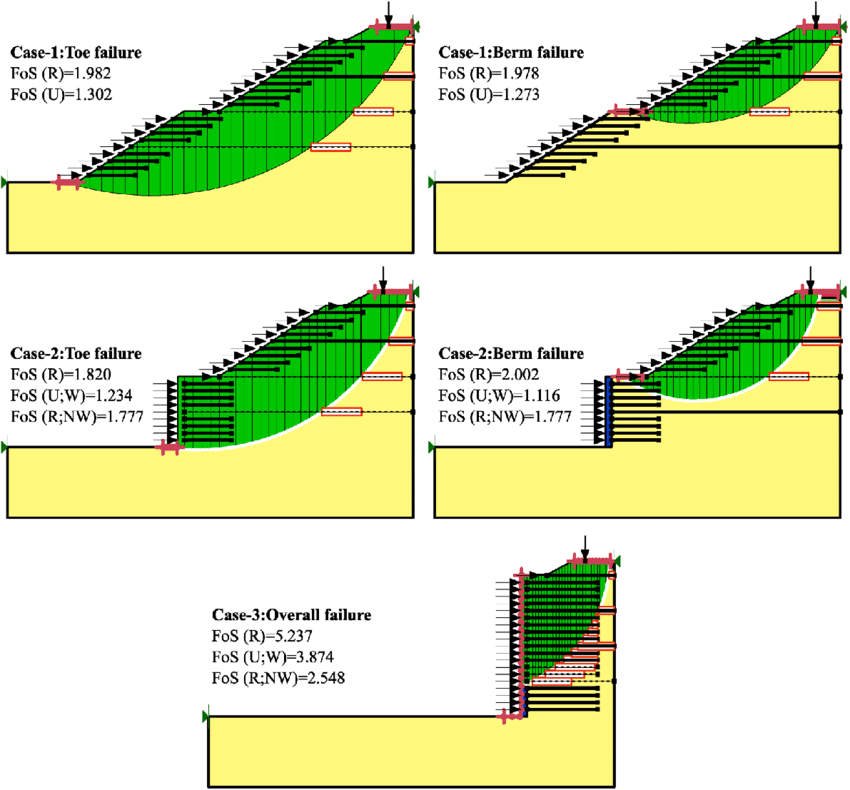

Factor of Safety (FoS)

Sumber: google.com

FoS is a quantitative indicator of slope stability:

- FoS > 1.25 → Stable

- 1.07 ≤ FoS ≤ 1.25 → Critical, requires monitoring

- FoS < 1.07 → Unstable, high risk of slope failure

The calculation compares shear strength (resisting forces) with driving forces.

🔎 Simple analogy: Think of car brakes on a downhill road. If the brakes are stronger than gravity, the car stops. If the brakes are weak, the car slides—similar to slope failure.

Slope Stability Analysis Methods

Sumber: google.com

1. Limit Equilibrium Methods (LEM)

- Bishop, Janbu, and Morgenstern-Price methods.

- Divide the slope into slices and calculate force & moment equilibrium.

- Widely used in coal and nickel mining due to speed and efficiency

2. Numerical Modeling

- Finite Element Method (FEM): models stress and strain distribution.

- Finite Difference Method (FDM): suitable for long-term dynamic analysis.

- Discrete Element Method (DEM): analyzes block interactions in fractured rock masses.

3. Probabilistic Analysis

Instead of producing a single FoS value, it calculates the probability of failure based on variations in parameters (cohesion, φ, etc.).

Case Studies in Indonesia

- Coal Mine in Kutai Kartanegara

Initial FoS of the disposal area: 1.108–1.756 → below safe limits.

Recommendation: slope angle 9° + bench height 7 m → FoS improved to 1.301 (safe) - Martabe Gold Mine

Geotechnical monitoring recorded movements of 5 mm/day. Back-analysis revealed actual cohesion was much lower than laboratory values.

Solution: redesigning slope geometry.

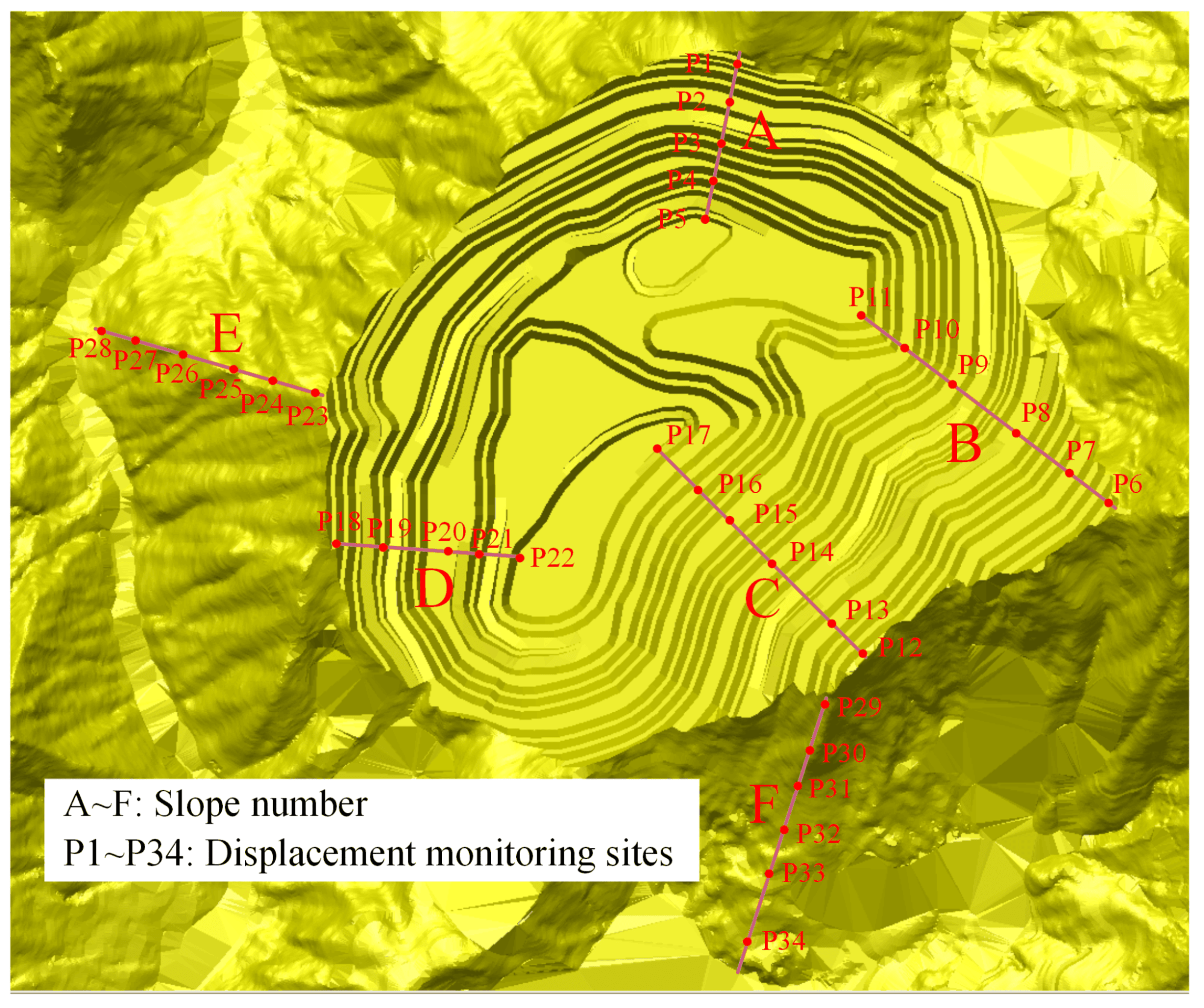

Modern Technologies

Sumber: google.com

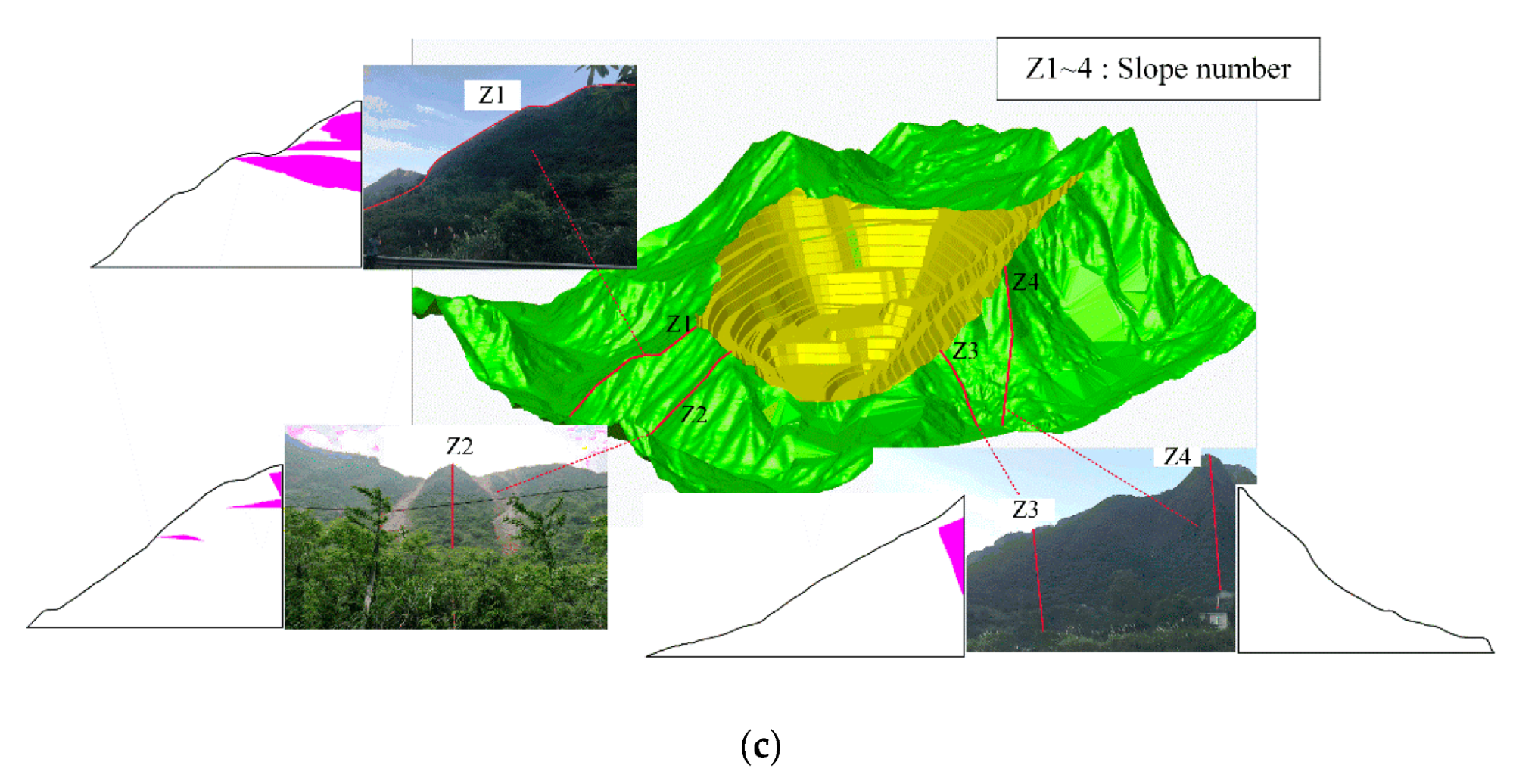

- Drone Photogrammetry & LiDAR: produce accurate 3D slope models.

- Radar Interferometry (InSAR): detects slope movement at millimeter scale.

- Slope Digital Twin: integrates geotechnical data, sensors, and real-time imagery for early prediction.

📌 Example: Research at Shizhuyuan Mine, China, combined FEM with real-time monitoring, enabling identification of at-risk slope zones before failure occurred.

Conclusion

Mine stability is the synergy of robust structural data, accurate analysis methods, and modern monitoring technologies. With this approach, companies can:

✔️ Ensure production continuity

✔️ Reduce material losses

✔️ Protect workers