In the mining industry, the success of an operation is not only measured by how much mineral is extracted, but also by how the mine design is planned from the very beginning. A well-prepared design not only determines productivity, but also safeguards worker safety and ensures environmental sustainability.

1. What Is Basic Mine Design?

Basic mine design is the process of developing the layout and geometry of a mine, which includes:

- Open-pit mines: defining the final depth, slope angles, berm width, ramps, and drainage systems.

- Underground mines: determining pillar dimensions, level spacing, ventilation systems, and escape routes.

The objective of mine design is not only to optimize reserves but also to balance technical, economic, safety, and environmental aspects.

An immature design can be catastrophic: slope failures, pillar collapses, financial losses, and damage to a company’s reputation.

2. Types of Tests as the Basis of Design

To ensure the design is not based on assumptions alone, a series of geotechnical, geomechanical, and hydrogeological tests are required. Below are the details:

a. Material Characterization Tests

- Soil/Rock Texture & Classification Tests

Identify whether the material is dominated by sand, silt, or clay.- Design benefit: helps determine haul road stability, foundation planning, and surface drainage.

- Physical Properties of Rock

Bulk density, porosity, moisture content, and compaction.- Design benefit: affects tonnage estimation, haul material density, and slope loading.

Mechanical Properties Tests

- Uniaxial Compressive Strength (UCS) & Triaxial Tests

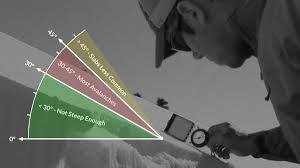

Measure compressive strength, elastic modulus, and deformation behavior.- Design benefit: determines safe slope angles and underground pillar dimensions.

- Direct Shear Test

Identifies cohesion (c) and internal friction angle (φ).- Design benefit: predicts slope failure potential and foundation stability.

c. Hydrogeological Tests

- Permeability & Consolidation Tests

Measure the ability of rock/soil to transmit water and its response to loads.- Design benefit: prevents pore water buildup, aids sump design, and dewatering systems.

- Slug Test & Pumping Test

Determine groundwater flow and hydrostatic pressure.- Design benefit: anticipates seepage that could weaken slopes or pillars.

d. Rock Mass Classification

- Rock Mass Rating (RMR), Q-System, Geological Strength Index (GSI)

Assess rock mass quality based on discontinuities, rock strength, and field conditions.- Design benefit: identifies support requirements (e.g., rock bolts, shotcrete, steel sets, cable bolts).

e. Monitoring & Instrumentation

- Field instruments: extensometers, piezometers, inclinometers, radar monitoring.

- Design benefit: provide real-time data on slope movements, water pressure changes, and rock mass deformation.

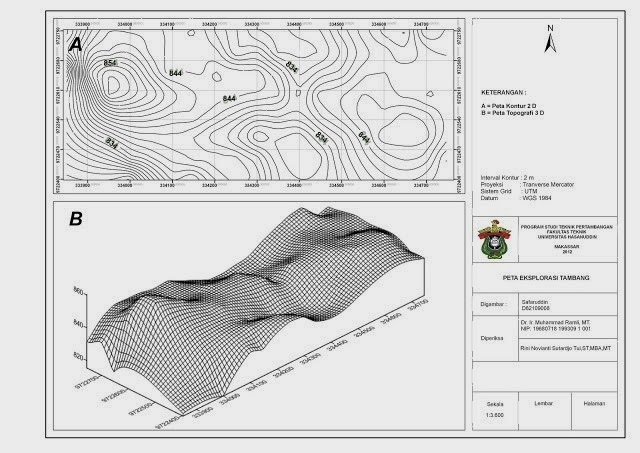

3. Linking Test Results to Design

The relationship between testing and design can be illustrated as follows:

- Slope Angle: defined by cohesion, friction angle, and UCS results.

- Ramp & Berm Width: influenced by rock mass classifications (RMR/Q-System) and failure predictions.

- Drainage Systems: aligned with permeability and pumping test results.

- Underground Pillars: minimum pillar dimensions depend on rock compressive strength and safety factors.

- Support Systems: selected based on rock mass quality and monitoring results.

In other words, tests are the language of data, and design is its translator.

4. Transformation in the Digital Era

Mine design today no longer relies solely on manual test results. Technological advancements now allow integration between:

- Geotechnical software: such as FLAC3D, Rocscience, or Plaxis for numerical simulations.

- Digital twins: virtual representations of mines for real-time geotechnical monitoring.

- AI & Machine Learning: analyze deformation patterns from sensor data to provide early warnings.

Laboratory test results are now combined with field sensor data, enabling designs to remain adaptive and continuously updated.

5. Conclusion

Basic mine design is not just a technical drawing on paper, but a comprehensive strategy rooted in geotechnical data.

- Without testing → design is merely a guess.

- Without design → test results lack direction for implementation.

Together, they form a synergy that ensures mines are safe, efficient, and sustainable.

At the end of the day, mining is not only about extracting minerals, but also about maintaining balance between exploitation, safety, and sustainability.

Sources:

Read, J. & Stacey, P. (2009). Guidelines for Open Pit Slope Design. CSIRO Publishing.

Hoek, E. & Bray, J.W. (1981). Rock Slope Engineering. CRC Press.